OCCUPATIONAL HEALTH AND SAFETY

Occupational safety and production culture are our number one priorities!

The Company’s main goal in occupational health and safety is to ensure workplace safety and pro tect the health of employees by preventing work-related accidents and occupational diseases, as well as improving the level of safety culture.

Management in the field of occupational safety is aligned with the Labour Code of the Russian Federation No. 197-FZ dated 30 December 2001 and sectoral and local regulations.

PJSC Rosseti South places a high priority on occupational safety because its employees are the most valuable resource and the secret to its success.

Health and Safety Management System

The establishment and operation of the occupational health and safety management system (hereinafter referred to as OHSMS) at PJSC Rosseti South takes into account state regulatory requirements for occupational health and safety, the commitments made on occupational health and safety, as well as international, interstate and national standards.

PJSC Rosseti South has the Regulations on the Occupational Health and Safety Management System.

The OHSMS applies to all structural subdivisions of Rosseti South, as well as employees of contractors.

Risk assessment is an important tool to identify hazards and risks in a timely and systematic manner and to take preventive measures.

An appropriate procedure is established for the identification (detection) of hazards and assessment of occupational risk levels at workplaces.

The results of hazard identification and assessment of risk levels at workplaces are communicated to employees in the following ways:

- By including in workplace health and safety briefings

- By posting summary data on the risk assessment results in publicly accessible places (information stands, occupational safety and health desks, etc.)

Information on detected (identified) hazards and occupational risk levels is used at all levels of occupational health and safety management.

A high professional level of training for the Company’s employees is one of the requirements for the OHSMS to operate effectively.

Occupational health and safety training activities for employees include:

- Occupational safety briefings upon entry to and in the course of employment

- On-the-job training (for certain categories of personnel)

- Training and knowledge testing in occupational safety, safe job methods and techniques

- Training in how to separate the person from the source of electric current, first aid techniques (for certain categories of employees)

- Training in the use and application of personal protective equipment (for certain categories of employees)

Knowledge and practical skills acquired by employees are analysed with due account of the results of on-the-job training, shadowing, emergency and fire drills, as well as the results of periodic observations (various types of control) of how the employee performs the functions and tasks assigned to him/her.

In order to make occupational safety training of employees more effective, structural subdivisions ensure the availability of occupational safety rules and instructions, as well as other materials necessary for safe performance of work.

Investigation of accidents

Work-related accidents, occupational diseases, micro-injuries (micro-damage) at the Company’s workplaces are be investigated and recorded.

The purpose of investigating the causes of accidents, occupational diseases and other injuries is to prevent the deterioration of employee health and safety and to identify deficiencies in how the OHSMS functions.

Measures to investigate and record accidents and occupational diseases include:

- Organising the reporting of accidents and occupational diseases to the competent authorities and organisations

- Organising and ensuring a proper and timely investigation of an accident and occupational disease, drawing up investigation materials in accordance with legal requirements

Identification and prevention of hazards

The Company identifies and prevents hazards in the course of the following activities:

- Assessment and management of occupational risks, with special attention paid to high-hazard jobs

- Special assessment of work environment

- Implementation of an operational risk assessment procedure immediately at the workplace before work begins

- Industrial control of labour conditions

- Prevention of accidents and elimination of their consequences

- Special-purpose, comprehensive and operational inspections

- Use of instruments, devices, equipment and (or) complexes (systems) of instruments, equipment (if available and feasible) that provide remote video, audio or other recording of work processes, and storage of the obtained information

Industrial safety

Pursuant to Article 2 of Federal Law No. 116-FZ dated 21 July 1997 “On the Industrial Safety of Hazardous Production Facilities”, PJSC Rosseti South operates 127 hazardous production facilities registered in the Unified State Register of Hazardous Production Facilities by the North Caucasus Department of the Federal Service for Environmental, Technological and Nuclear Supervision on 15 October 2020 (registration certificate No.

A total of 455 technical devices (truck cranes, hoists (derricks), gas supply networks, and gantry cranes) are operated at the hazardous production facilities of PJSC Rosseti South.

MEASURES TO ENSURE INDUSTRIAL SAFETY REQUIREMENTS IN 2023

Technical inspections, industrial safety examinations of technical devices used at hazardous production facilities

Insurance of hazardous production facilitiesTraining and certification of employees in the field of industrial safety

Inspections in the context of industrial control over compliance with industrial safety requirements

PJSC Rosseti South did not record any accidents at hazardous production facilities.

In order to ensure readiness for actions to contain and eliminate the consequences of an accident at hazardous production facilities of hazard class III (gas consumption networks), emergency response plans were developed and approved.

Contracts for operational maintenance of hazardous production facilities of hazard class III were concluded with emergency rescue teams.

In order to prevent accidents at the hazardous production facilities of Rosseti South, technical devices are to be operated in accordance with the requirements of regulatory legal acts in the field of industrial safety by trained and certified employees. The branches have an instruction in place that defines the actions of employees in emergency situations during the operation of technical devices at the facilities.

Work-related injuries and work-related ill-health

PJSC Rosseti South has the Occupational Health and Safety Policy of the Rosseti Group Enacted by Order of PJSC Rosseti South No. 659 dated 30 October 2023. in place.

The policy is communicated to all persons, contractors doing business for the Company and sightseers visiting the Company.

To implement the Policy, as well as the obligations stated therein, and to achieve the objectives in occupational health and safety, the Company plans, develops and integrate measures to implement OHSMS procedures.

Special assessment of working conditions is a unified set of consistently implemented measures to identify harmful and (or) dangerous factors of the production environment and labour process and assess the level of their impact on the employee.

Employees who perform their duties at workplaces that do not meet state regulatory requirements for occupational health and safety are paid compensation for work in hazardous working conditions, are granted additional paid leave, increased wages, and are provided with milk or other equivalent products (monetary compensation).

For protection against harmful and (or) hazardous factors of the production environment and (or) pollution, as well as at work performed in special temperature conditions, employees are provided free of charge with personal protective equipment and washing agents that received confirmation of conformity in accordance with the procedure established by the legislation of the Russian Federation on technical regulation.

Personnel of PJSC Rosseti South are completely furnished with special clothing and safety shoes.

In order to monitor, control and evaluate the OHSMS performance, the health of employees is monitored, including preliminary and periodic medical check-ups (examinations) and psychiatric examinations.

PJSC Rosseti South organises medical examinations once every two years for employees whose workplaces have harmful and/or hazardous production factors, as well as vehicle drivers, and annually for persons admitted to work at heights.

The measures of the Comprehensive Programme for Personnel Injury Risk Reduction of PJSC Rosseti South for 2023 were implemented.

In 2023, there was a group accident with a minor outcome involving employees of Azovsky power grid region of Rostovenergo, a branch of Rosseti South. The cause of the accident was a traffic offence by an third-party driver. Based on the results of the investigation, the circumstances of the accident were brought to the attention of the labour collective, and an unscheduled briefing on compliance with traffic rules was conducted for all driving personnel.

No cases of work-related ill-health among the personnel of PJSC Rosseti South were registered in

In 2023, the Company continued to work towards the Zero Injuries Concept, one of the development areas of safety culture.

Significant events in 2023:

- A transition from unannounced inspections of working teams to continuous monitoring of employees, relevant documents were issued, and employees received appropriate training

- Training sessions by zero Injury trainers at power grid regions and for work teams

- Promotion of safety compliance among employees and clarification of the essence of new trends in the field of occupational safety

- Training events with leaders of change

- Changed approaches to the monthly occupational safety day procedures and video recording of employees’ actions in electrical installations

- Video instructions filmed for employees on the correct use of security equipment with smartphone recognition

- Solutions for gamification of work with personnel in order to study and practically apply the requirements of the Rules

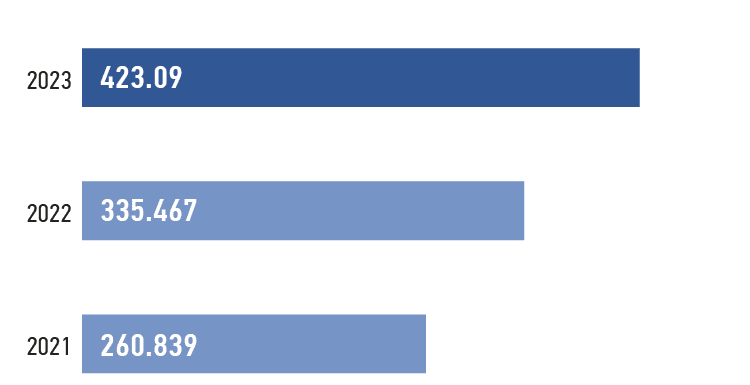

Indicators | 2021 | 2022 | 2023 |

|---|---|---|---|

For employees: | |||

Number of victims of fatal work-related accidents, number of fatal work-related accidents | 0 | 0 | 0 |

Number of people injured in work-related accidents with severe injuries, number of work-related accidents with severe injuries | 0 | 0 | |

For persons who are not employees, but whose work and (or) workplace is controlled by the Company: | |||

number of victims of fatal work-related accidents, number of fatal work-related accidents | 0 | 0 | 0 |

number of people injured in work-related accidents with severe injuries, number of work-related accidents with severe injuries | 0 | 0 | 0 |